top of page

DISEÑO

Evolución del diseño

Desde el primer hasta el tercer equipo de diseño sénior, el pie protésico ha experimentado numerosas iteraciones. La evolución del diseño es crucial en el camino hacia la excelencia. En los últimos años, Step Up Prosthetics ha desarrollado varios diseños con el objetivo de optimizar la calidad, priorizar la facilidad de fabricación y minimizar los costos.

Year 1

Drawing inspiration from the human foot as well as developing an in depth understanding of what makes a prosthetic foot functional, this was one of the early designs from the Year 1 team.

Year 1

The final design from Year 1 maintains the J shaped curve while using carbon fiber. Overall this design took leaps in transitioning from a lower quality SACH foot by reducing the energy loss and increasing energy return.

Year 2

Year 2 dove further into the use of 3D printing by the previous year. Innovating to effectively cast a 3D printed insert into a urethane shell. The insert featured a split down the center to better support the flexibility needed to support the amputee.

Year 3

In order to mimic the weight of a real foot, the Year 3 team created fillers to not only reduce weight but serve the added benefit of increasing flexibility and durability.

Year 3

The final design from Year 3 features a flexible filler to help distrubyte the amputee's load and preserve a low weight for the prosthetic. The design is customizable for the patient.

Year 1

Drawing inspiration from the human foot as well as developing an in depth understanding of what makes a prosthetic foot functional, this was one of the early designs from the Year 1 team.

Year 1

The final design from Year 1 maintains the J shaped curve while using carbon fiber. Overall this design took leaps in transitioning from a lower quality SACH foot by reducing the energy loss and increasing energy return.

Year 2

Year 2 dove further into the use of 3D printing by the previous year. Innovating to effectively cast a 3D printed insert into a urethane shell. The insert featured a split down the center to better support the flexibility needed to support the amputee.

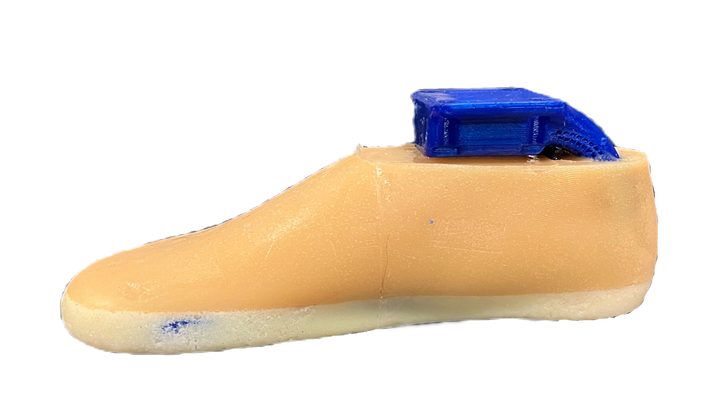

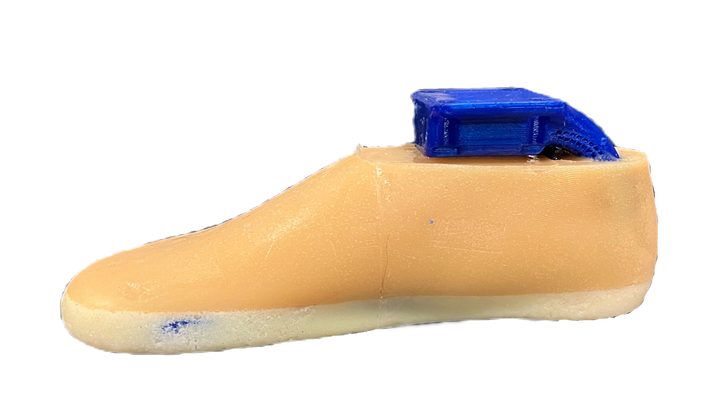

Year 3

In order to mimic the weight of a real foot, the Year 3 team created fillers to not only reduce weight but serve the added benefit of increasing flexibility and durability.

Year 3

The final design from Year 3 features a flexible filler to help distrubyte the amputee's load and preserve a low weight for the prosthetic. The design is customizable for the patient.

Year 1

Drawing inspiration from the human foot as well as developing an in depth understanding of what makes a prosthetic foot functional, this was one of the early designs from the Year 1 team.

Year 1

The final design from Year 1 maintains the J shaped curve while using carbon fiber. Overall this design took leaps in transitioning from a lower quality SACH foot by reducing the energy loss and increasing energy return.

Year 2

Year 2 dove further into the use of 3D printing by the previous year. Innovating to effectively cast a 3D printed insert into a urethane shell. The insert featured a split down the center to better support the flexibility needed to support the amputee.

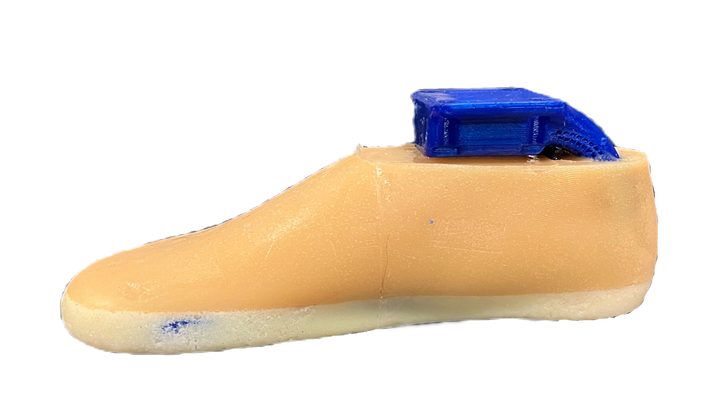

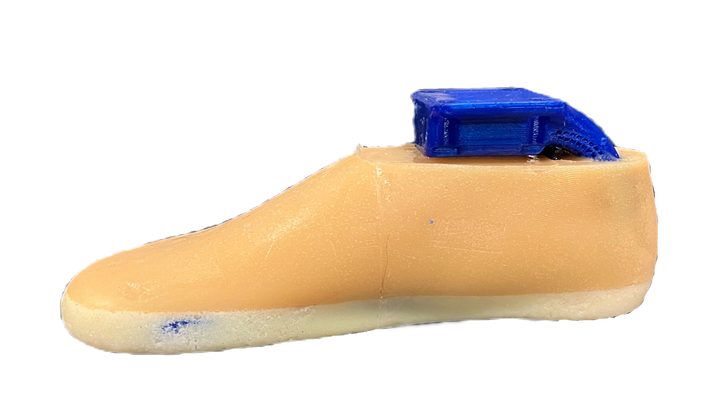

Year 3

In order to mimic the weight of a real foot, the Year 3 team created fillers to not only reduce weight but serve the added benefit of increasing flexibility and durability.

Year 3

The final design from Year 3 features a flexible filler to help distrubyte the amputee's load and preserve a low weight for the prosthetic. The design is customizable for the patient.

Year 1

Drawing inspiration from the human foot as well as developing an in depth understanding of what makes a prosthetic foot functional, this was one of the early designs from the Year 1 team.

Year 1

The final design from Year 1 maintains the J shaped curve while using carbon fiber. Overall this design took leaps in transitioning from a lower quality SACH foot by reducing the energy loss and increasing energy return.

Year 2

Year 2 dove further into the use of 3D printing by the previous year. Innovating to effectively cast a 3D printed insert into a urethane shell. The insert featured a split down the center to better support the flexibility needed to support the amputee.

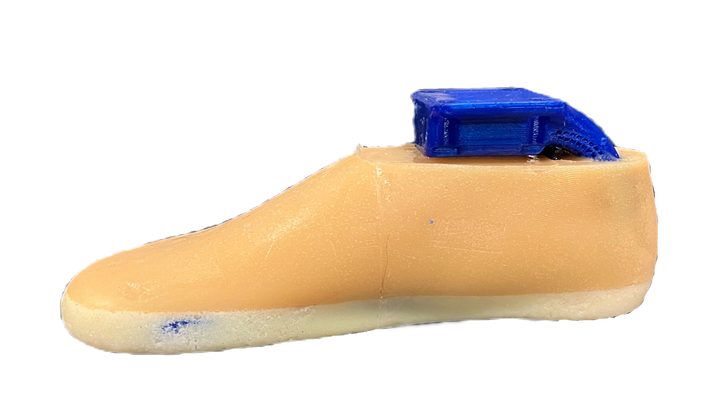

Year 3

In order to mimic the weight of a real foot, the Year 3 team created fillers to not only reduce weight but serve the added benefit of increasing flexibility and durability.

Year 3

The final design from Year 3 features a flexible filler to help distrubyte the amputee's load and preserve a low weight for the prosthetic. The design is customizable for the patient.

Year 1

Drawing inspiration from the human foot as well as developing an in depth understanding of what makes a prosthetic foot functional, this was one of the early designs from the Year 1 team.

Year 1

The final design from Year 1 maintains the J shaped curve while using carbon fiber. Overall this design took leaps in transitioning from a lower quality SACH foot by reducing the energy loss and increasing energy return.

Year 2

Year 2 dove further into the use of 3D printing by the previous year. Innovating to effectively cast a 3D printed insert into a urethane shell. The insert featured a split down the center to better support the flexibility needed to support the amputee.

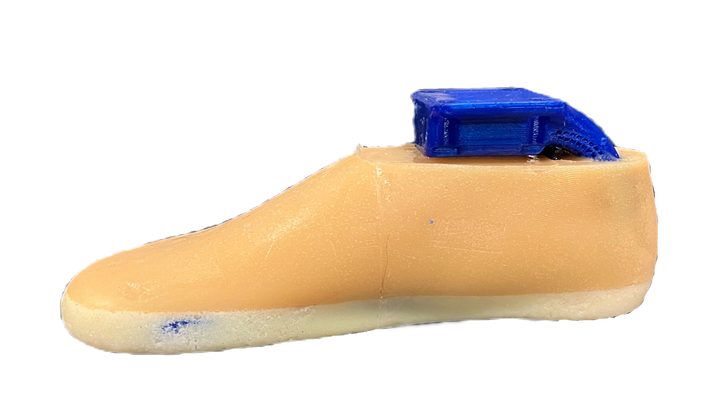

Year 3

In order to mimic the weight of a real foot, the Year 3 team created fillers to not only reduce weight but serve the added benefit of increasing flexibility and durability.

Year 3

The final design from Year 3 features a flexible filler to help distrubyte the amputee's load and preserve a low weight for the prosthetic. The design is customizable for the patient.

Year 1

Drawing inspiration from the human foot as well as developing an in depth understanding of what makes a prosthetic foot functional, this was one of the early designs from the Year 1 team.

Year 1

The final design from Year 1 maintains the J shaped curve while using carbon fiber. Overall this design took leaps in transitioning from a lower quality SACH foot by reducing the energy loss and increasing energy return.

Year 2

Year 2 dove further into the use of 3D printing by the previous year. Innovating to effectively cast a 3D printed insert into a urethane shell. The insert featured a split down the center to better support the flexibility needed to support the amputee.

Year 3

In order to mimic the weight of a real foot, the Year 3 team created fillers to not only reduce weight but serve the added benefit of increasing flexibility and durability.

Year 3

The final design from Year 3 features a flexible filler to help distrubyte the amputee's load and preserve a low weight for the prosthetic. The design is customizable for the patient.

Proceso de diseño

Conozca el proceso de diseño del pie protésico Step Up actual.

bottom of page